I have been coming across an ever increasing issues with my laser cutter (an LS1290) and I'm really starting to struggle with what to do?

The engraving function is non-functioning completely (probably best to save this one for a different thread?) but the cutting seems to be getting worse to the point where my output is almost unusable.

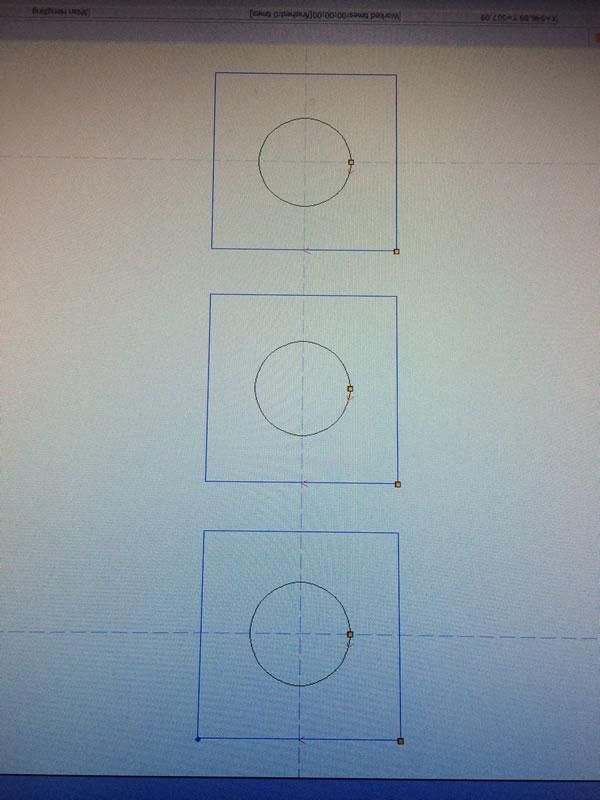

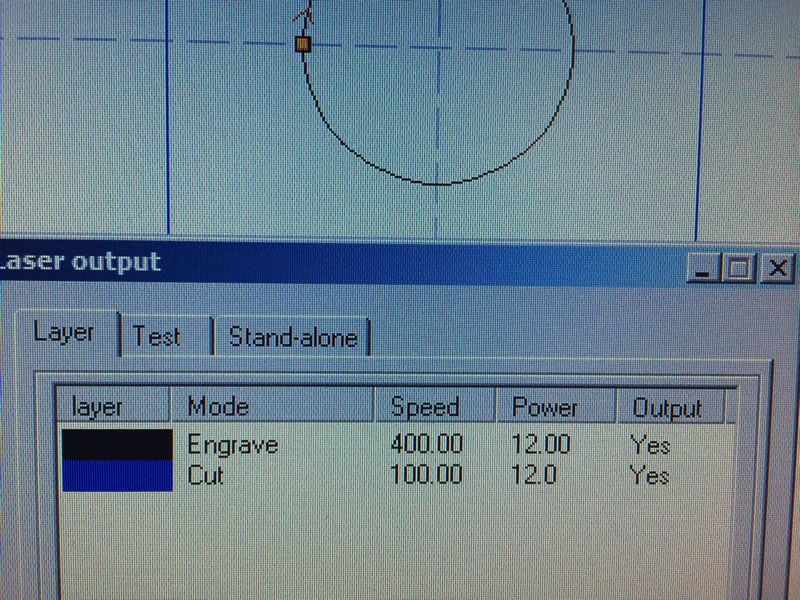

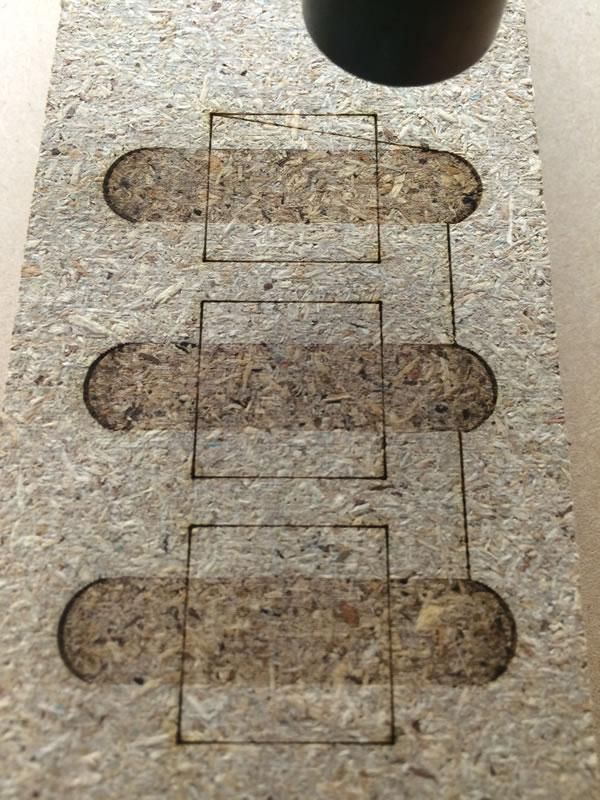

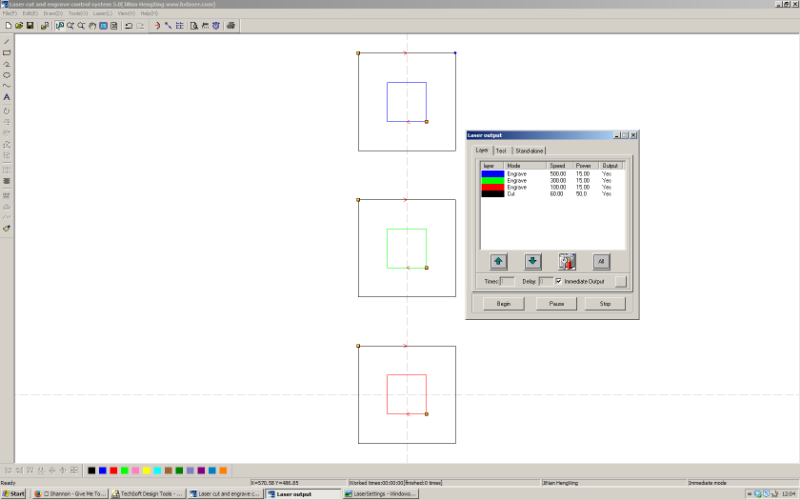

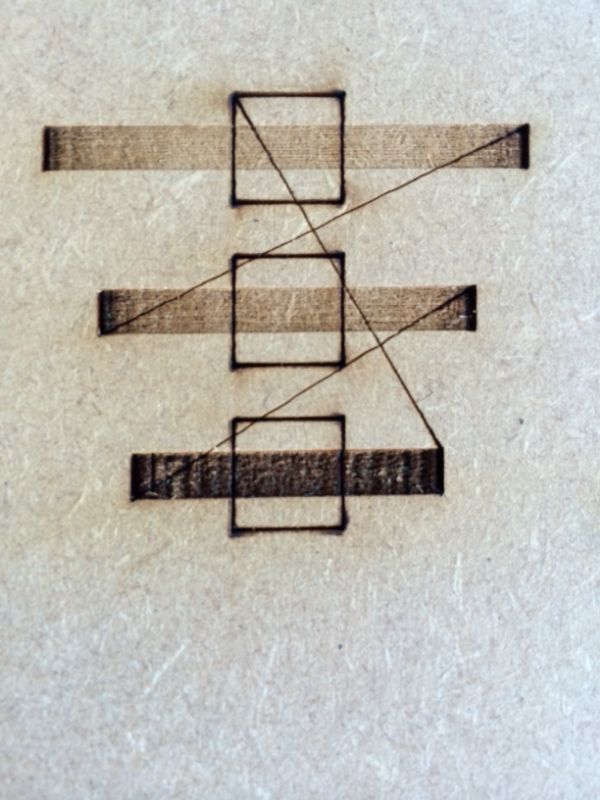

In the absence of the engraving function, for the time-being I've been using the laser on a high speed/low power to engrave lines, which work quite well. Until recently where the line quality has degraded massively. It now produces nothing but wobbly lines and the line often cuts out/disappears mid line.

I've got a couple of example shots of some pieces that I did a little while back and how they look when using the machine now. You can clearly see the difference in the line quality. Both pieces were cut using the same settings and the same material.

I really don't know where to start?

The laser tube is very recent (only about 30 hours use) and so is the power supply. I've cleaned the lenses, checked for bubbles in the tube, checked, double checked and triple checked the alignment and nothing seems to resolve this issue?

I don't know if it's a multitude of issues? I have to regularly align the laser because it goes out of alignments within about 10 mins of cutting! I'm having trouble even cutting 3mm plywood now where it used to slice through it with ease.

If anyone has seen this issue or knows what could be causing it, I'd be really grateful for some advice?

Also, if anyone is in Bristol and fancies taking a look at the machine (I'll pay) I'd love someone with some experience to help me get to the bottom of these issues??

Many thanks for your time

Bruce (at his wits ends!)